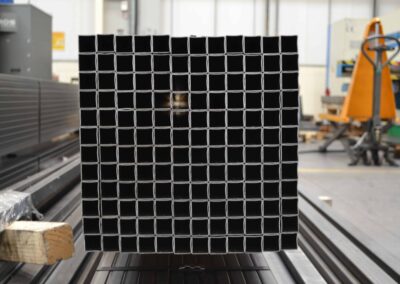

HIGH QUALITY, PRECISION PERFECT LASER TUBE CUTTING SERVICE

Enquire NowRapid production of high quality tubular and box section components.

Gratnells Engineering aims to be different. Not only do we provide a high volume tube laser cutting service, we specialise in short run, quick turnaround projects. This is particularly suitable for bespoke automotive and point-of-sale components where the minimum quantities can start at one.

Tube laser cutting offers a quick route to a precise finish, eliminating conventional, time-consuming stages such as marking out, sawing and finishing whilst delivering significant cost savings.

If you can design it we can make it.

What can we do for you?

- Quoting for ‘laser cutting only’ jobs within a day.

- We can turn around tube laser cutting jobs quickly, usually within 3-5 days from receipt of order

- We can offer lasered holes and parts with greater accuracy and speed

- With our sophisticated software, we can process your parts from a variety of media, including 3D models, xt files and solid works

- We also offer a powder coating service you can learn more about this here

Fast turnaround

We can turnaround laser tube cutting jobs within 3-5 days from receipt of order

Precision cutting

With two state of the art laser machines we are capable of cutting even the most precise of designs

Fast quoting

We aim to have a quote to you within a day for laser cutting only jobs

At Gratnells Engineering we believe that quality and customer service are every bit as important as price and lead time.

For service and attention to detail that you won’t find elsewhere, email your tube lasering needs to us today for a speedy quote: [email protected] or tel: 03330110570

Technical Details

BLM LT5

| Round tube | diameter min. 12mm – max. 120mm |

| Square tube | min. 12 x 12mm – max. 100 x 100mm |

| Rectangular, flat oval, semi flat oval tubes | min. 10 x 12mm – max. 120 x 70mm |

The LT5 is equipped with:

- Automated unloading and support system for precut lengths up to 6100 mm

- The unloader separates, collects and palletises the finished parts

- For applications where stainless tube is involved (food industry, furnishings, exhaust pipes, catalytic pots) the cutter is equipped with a module (the spoon) that maintains the cleanliness of the internal tube surface whilst machining

- Automatic weld seam detection

- High speed processing

- A 1 kW laser source

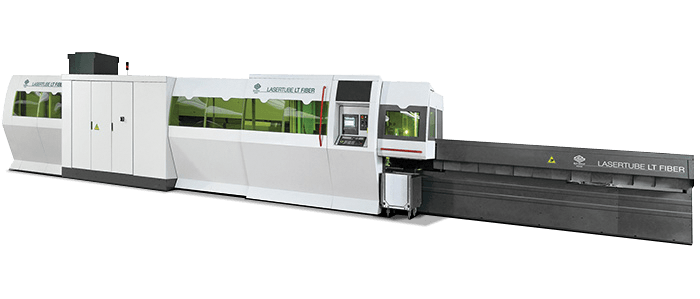

BLM LT FIBER

| Round tube | diameter min. 12mm – max. 140mm |

| Square tube | min. 12 x 12mm – max. 120 x 120mm |

| Rectangular, flat oval, D-shaped, elliptical tube | min. 12 x 10mm – max. 140 x 100mm |

The LT FIBER is equipped with:

- The right grip for every tube, meaning we can handle tubes of any weight without deforming the walls.

- The machine manages changeovers automatically: loading, handling and unloading are automatically adjusted from one job to the next

- Programmable unloading to various position meaning we do not need to manually separate parts from different orders.

- A 2 kW laser source

GET IN TOUCH

If you would like more information on any of our engineering services or a quote please call us on +44 (0) 3330110570, send us a message here or email [email protected]